Another technological innovation

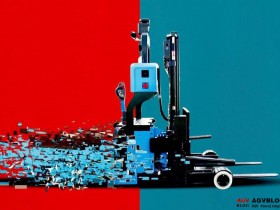

SAT intelligent stacking technology + AGV collaborative operation

The number of goods stacked can be increased by 30%

Order picking efficiency increased by 40%

▼

Dutch company SAT Technologies has launched an intelligent stacking technology that can be used as an auxiliary tool on any brand and any type of AGV, and can increase the number of goods stacked by 30% and order picking efficiency by 40%.

The core of the technology: the robot can automatically calculate the position where each cargo should be placed, and the picker only needs to place the cargo according to the prompt. In layman's terms, it is through laser projection technology identification to help the picker to place and pack the goods more reasonably, improving space utilization.

Innovation: The biggest innovation of this solution lies in the integration of SAT intelligent stacking technology and the picking AGV to work together to improve overall productivity.

As we all know, order sorting is a very important part in the warehouse. The picker ’s search for pallets and stacking is a non-productive step in the order picking process (mostly artificially completed). Greatly reduce transportation efficiency. After the SAT stacking auxiliary tool developed by SAT Technologies is used on the AGV intelligent guided vehicle, the intelligent stacking software can calculate the most effective stacking order and the most intelligent AGV walking route in advance, and send it to the AGV order selection at the same time. Device.

Working in a specific area, each order selector selects only those orders located in its area, AGV covers the shortest travel distance according to the most intelligent route, and the time saved by SAT technology and AGV working together is converted into higher productivity , Thereby reducing operating costs.

Work flow

After receiving the order, the picker arrives at the position of the goods according to the prompt. The laser above the AGV projects the correct position and appropriate position where the goods should be placed. When the picker places the goods on the AGV, the camera will automatically check whether the position and the carton number are correct. , such as the location of the error or mistake goods, SAT promptly corrected by laser projection remind pickers correct.

Advantages of SAT intelligent stacking technology + AGV collaborative operation

1. Accurate and stable

Through robot calculation, the optimal stacking method of the goods on the pallet is ensured, which makes the goods more stable and accurate.

2. Security

In the past, pickers used their own experience to place and stack goods, not only wasting time, but if the goods were unreasonably stacked, they would easily collapse during transportation and cause danger. The SAT intelligent stacking technology can make the stacking more stable and optimize orders and pallets.

3. Improve warehouse operation efficiency

After testing, the use of mobile carts equipped with SAT and AGV can increase the number of cargo stacks by 30%, the error rate is 0, and the efficiency of cargo picking is increased by 40%. The most important thing is that this technology is only integrated on the AGV, without the need to replace other equipment in the warehouse.

Scope of application

This technology is mainly integrated with AGV automatic guided vehicles. SAT is suitable for all types of goods and can also be integrated with any brand of AGV. In addition, the technology can also be integrated on the truck, saving about 30% of the space for the truck and realizing multiple loads.

The editor has only one feeling: the gold content of the picker's work is getting lower and lower, and the hard work will become easier.

The development of science and technology has been able to make the picking in the warehouse a "fool" job, and everyone can easily handle it. In the past, the goods were moved by human power, and then AGV appeared, and the transportation was by robots. However, the work of picking and stacking goods still needs human operation. Go! Now that intelligent stacking technology has emerged, employees do not even need to think or place on the basis of experience or even picking and palletizing. They can rely on computers!

Author | Rogo Xiaowei

Source | LogTV

This article is the author's personal opinion and does not represent the logistics salon's position