Automated Guided Vehicle (AGV) refers to a transport vehicle equipped with electromagnetic or optical automatic guidance devices that can travel along a prescribed guidance path, has safety protection and various transfer functions, and is used in industrial applications. Removable vehicles that do not require drivers are powered by rechargeable batteries. Generally, the computer can be used to control its travel route and behavior, or the electromagnetic path (electromagnetic path-following system) can be used to set up its travel route. The message moves and moves.

AGV is characterized by wheeled movement. Compared with walking, crawling or other non-wheeled mobile robots, it has the advantages of fast action, high work efficiency, simple structure, strong controllability, and good safety. Compared with other equipment commonly used in material transportation, AGV's active area does not need to lay rails, support frames and other fixed devices, and is not limited by the site, road and space. Therefore, in the automated logistics system, it can fully reflect its automation and flexibility to achieve efficient, economical, and flexible unmanned production.

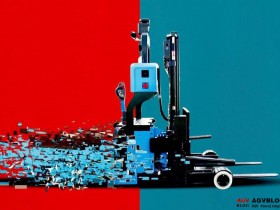

Assembly type AGV

AGV classification:

1. Assembly type AGV. Assembly type AGV is currently mainly used in assembly workshops of automobile companies. At present, the domestic assembly type AGV is mainly developed and designed by Shenyang Xinsong Robot independently. Below our team assembled AGV for further classification:

Single lift assembly type AGV

This type of AGV mainly serves automotive companies. Automobile companies only need the AGV to assemble the engine and one equipment on their own production and assembly lines, so the single-lift AGV was born in the automotive company.

Single lift assembly type AGV

Double lift assembly type AGV

The dual-lift AGV is also mainly used to serve automobile companies, such as household sedan cars. On the production line of the automobile company, the front side of the AGV is responsible for lifting the main parts of the engine, and the rear lifting is mainly responsible for the main parts of the rear axle. Carry out the necessary assembly according to the production line of the car company.

Double lift assembly type AGV

Three-lift AGV

In recent years, the new technology in the automotive industry has developed rapidly, from traditional gasoline and diesel passenger cars to hybrid electric vehicles and pure electric vehicles. This development has driven higher requirements for the combined load of AGV in the AGV industry. AGV needs to be able to Provide greater lifting capacity to carry large-capacity battery pack assembly work.

Three-lift AGV

The AGV-M-A1500 (3) AGV is based on the traditional three-lift AGV-manned lift, powertrain lift, and rear axle assembly lift. The newly developed large-tonnage powertrain + battery assembly is lifted. The replacement of the original powertrain lift can meet the load requirement of 2 tons of single lift, and at the same time ensure that the car occupies a small space in the width direction, which is convenient for the installation operation of the car assembly operator.

The AGV-M-A1500 (3) AGV was successfully applied to German automobile manufacturers this time, breaking the original German barrier to the assembly type AGV. It has established an excellent application case for future market development.

The AGV-M-A1500 (3) AGV not only applies the newly developed large-tonnage power assembly + battery assembly technology, but also has dual anti-collapse synchronous protection, push rod type automatic charging system, and low-level operating platform for the follower wheel. And compact manned lifting and other new technology applications.

The AGV-M-A1500 (3) AGV is a development integration body of the combined AGV technology in the automotive assembly field of the Smart Mobile Robot Division of Xinsong Company for many years, and represents an important step for the development of assembled AGV.