The docking method of the AGV docking platform includes a control terminal, a rotation mechanism, a translation mechanism, a load-bearing platform, and first, second, and third proximity sensors. The rotation angle of the platform, the translation mechanism is used to advance or retreat the load-bearing platform. The middle part is electrically connected to the control terminal; compared with the prior art, the docking method of the AGV docking platform adjusts the parallelism of the load-bearing platform by comparing the distance values D1 and D2, and adjusts the position of the load-bearing platform by comparing the distance values D3 and D3 ', In this way, the docking accuracy of AGV equipment is improved. When adjusting the positioning accuracy, there is no need to adjust the AGV car body. It has the advantages of simple docking method, high positioning accuracy and easy implementation.

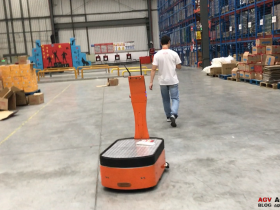

AGV docking platform

The AGV docking platform docking method is characterized by including a control terminal, a rotation mechanism, a translation mechanism, a load-bearing platform, and first, second, and third proximity sensors. The rotation mechanism and the translation mechanism are all provided on the AGV car body, and the rotation mechanism Used to adjust the rotation angle of the load-bearing platform, the translation mechanism is used to advance or retreat the load-bearing platform, the first and second proximity sensors are provided at both ends of the side wall of the load-bearing platform and are electrically connected to the control terminal, and the third proximity sensor is provided at the load-bearing The middle of the side wall of the platform is electrically connected to the control terminal; after the AGV reaches the docking station, the first proximity sensor detects the distance value D1 from the load-bearing platform to the dock and transmits it to the control terminal, and the second proximity sensor detects that the load platform is The distance value D2 of the dock is transmitted to the control terminal. The control terminal controls the rotation mechanism to adjust the angle of the load-bearing platform according to the size of the distance values D1 and D2 to make the load-bearing platform parallel to the dock; the preset docking station is docked with the dock The distance is D3 'and transmitted to the control terminal, the third proximity sensor detects the distance value D3 from the load-bearing platform to the dock and transmits it to the control terminal, the control terminal The distance value D3 control translation mechanism forward or backward, when D3 = D3 ', the translation means is stopped to complete the docking with the docking pier.