The sensor is one of the important technologies that restrict the development of the AGV car system. The sensor technology is very different between the AGV car's “ barely usable” and “easy to use”. Can you develop a stable and reliable AGV product? The first thing to look at is whether AGV manufacturers have the ability to develop core underlying technologies such as sensors. The reason why the intelligent AGV car system can operate accurately and stably is because a large number of low-level sensor technologies are developed. It can accurately sense the status of itself, the operating object and the working environment through various AGV-specific sensors, and the location of the AGV status information. Displacement, velocity, acceleration, etc. to complete self-adaptation, the perception of the operating object (peripheral hardware) and the external environment is realized by an external sensor. The data support required for control of the AGV trolley or AGV control system is provided by a variety of internal and external sensors.

Sensor technology is the key basis for automatic control and automatic adjustment of AGV car itself. It is also the key technology for data calculation of AGV central control system. The level of sensor technology of AGV manufacturers greatly influences and determines the function of AGV system. . The higher the sensor technology, the higher the automation of the designed AGV system. The sensors of the intelligent AGV car developed are dedicated sensors developed independently for the application characteristics of the wheeled mobile robot. In a complete AGV logistics system, if the sensing detection technology cannot be fully applied to timely and accurately detect the parameters of the controlled object and convert it into a signal that is easy to transmit and process, the AGV needs for the system. The control information is not available, which makes the entire system unable to work reliably and reliably.

Most of the domestic AGV manufacturers rely mainly on the cottage and the purchase of Japan's last century elimination technology for simple assembly, let alone the development of sensor technology, so a large number of "strongly active" AGV products, stability and reliability are also not To ensure that many of them are face-to-face projects, they have not really realized the intelligence of the AGV car. Mainly manifested in:

(1) Advanced calculation, simulation and design methods;

(2) Advanced micromechanical technology;

(3) Advanced device screening and testing technology;

(4) Reliability test methods and other aspects.

Therefore, AGV vendors must strengthen the underlying technology research to improve the overall reliability of the AGV. A responsible AGV system provider must first have the following technology development capabilities:

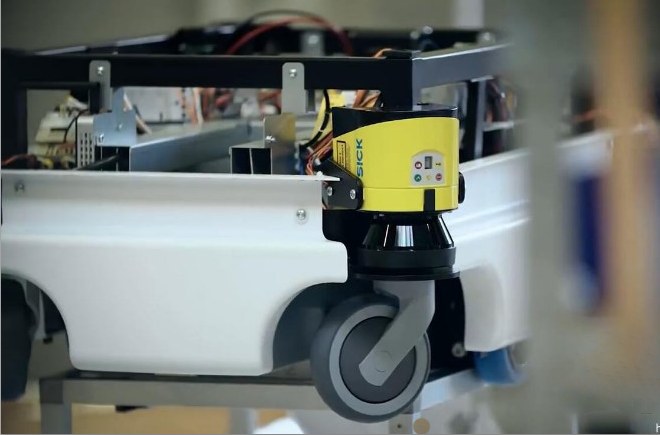

1. Ability to screen or develop new sensitive devices: through microelectronics, optoelectronics, electrochemistry, information processing and other disciplines, and can penetrate and comprehensively utilize these technologies, and develop AGV-specific sensors based on these new sensitive devices.

2. High precision: Developed a new sensor with high sensitivity, high precision, fast response and good interchangeability to ensure the reliability of AGV.

3. Miniaturization: Miniaturization of sensors through the development of new materials and processing technologies.

4. Micropower and Passivation: Develop micro-power sensors and passive sensors.

5. Intelligent digitization: Breaking through the traditional or general-purpose sensor function, it is no longer a single analog signal, but a digital signal processed by a microcomputer, a smart sensor with control function.