3.1 AGV performance parameters

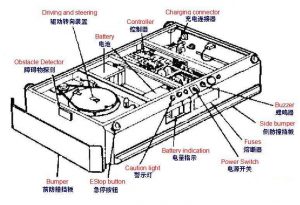

The AGV designed in the article is mainly composed of a car body, an on-board controller, a battery, a communication device, etc. The mechanical system is the basis of the entire AGV, and all other devices are loaded. The rationality of the mechanical system design determines the performance of the AGV. The specific parameters of the logistics AGV are shown in Table 1.

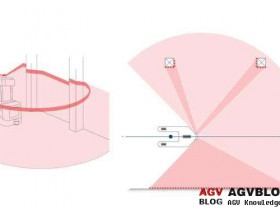

AGV structure

3.2 Design and implementation of AGV mechanical system

(1) The structure of the car body. The structure of the AGV trolley mainly includes three aspects: steering form, drive form and number of axles. The single-drive form structure is mostly used for the three-wheeled vehicle body structure. This type of vehicle structure can realize the left and right turning, forward and backward of the trolley. The structure has low requirements on the ground and good grip, and is mostly used for small AGV. The differential drive body consists of a four-wheel model and a three-wheeled model that enables the car to turn left and right, forward and reverse, and spin in place. The car is turned compared to the single-drive version. The effect is better. The four-wheel model has higher requirements on the flatness of the ground, and the adaptability of the Xiang is relatively poor, which is not suitable for outdoor work. The double-drive form is more common in four-wheel models. Its main advantage is that it can better control the body changes during the movement process. It can be used in special working environments. The main disadvantage is that the car has poor adaptability and relatively high cost. . The multi-wheel drive type is mostly used in the eight-wheel model. The structure of the vehicle is complex, costly and difficult to control, and is often used in the heavy-duty industry.

(2) Body structure and layout. The main function of the body is to control the original device and support all the mechanical parts. Therefore, the design of the body should pay attention to its rigidity and strength, so that its performance can meet the smooth running and acceleration of the car body, and it is welded by steel structure or steel pipe. The outer casing is made of sheet metal sheet metal, which reduces the weight of the body on the basis of rigidity and strength. The body layout should take into account the balance of the body, place the battery in the middle of the bottom of the frame, and place the motor driver, electrical components, PLC controller, etc. on the frame.