There are many types of AGV (unmanned automatic navigation trolleys), such as shifting AGV, handling AGV, assembly type AGV, etc., which are called various types. In fact, according to the functions of AGV, they can be divided into two categories: simple handling. Type AGV and assembled AGV. The handling type AGV is a simple handling tool. The biggest difference from the previous hand-pushing logistics trolley is that it is fully automated, unmanned, and can be automatically operated according to the set path, which can replace the manual handling method. According to the different types of goods to be transported, the different requirements of the load capacity, the overall design of the handling type AGV trolley is slightly different.

Lightweight items can be handled by light-weight AGVs, which are characterized by small and flexible body design. Due to the low load capacity requirements, small drives can be used to save energy and space. The handling of heavy-duty products can be carried out with heavy-duty AGV, and the overall size of heavy-duty AGV trolleys is expanded, such as large countertop heavy-duty AGV. This type of AGV car is made of sturdy metal material, equipped with a large drive, powerful power supply, and can carry several tons of load. It is generally suitable for outdoor transportation.

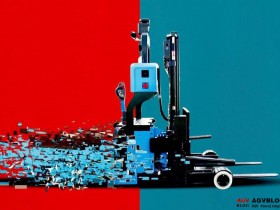

The difference between the assembled AGV and the simple handling AGV is the complexity of the functions, and it can handle complicated operations such as loading and unloading, and then carry out the handling of articles. Typical assembled AGVs include robot AGV, roller AGV, forklift AGV, and lift platform AGV. These AGV types have been improved on the basic car body to add some functions to achieve a series of complex actions.

The assembly type AGV trolley is more automated than the handling type, and the assembled AGV can completely liberate the labor force and realize the integration of handling and loading and unloading functions. Between the stations, the AGV carries the goods, and each time a station stops, the goods are loaded and unloaded. This type of AGV can be docked with production lines such as production lines, ramps, etc., and the items completed on the ramp and on the production line are assembled to the AGV and then transferred. The assembled AGV is generally a heavy-duty AGV, and the load capacity is higher than that of the transport type. Therefore, the design of the vehicle body is usually large, and it is suitable for the transfer and transportation of large products such as automobiles.