At present , the demand for AGV robots in China is strong and the demand areas are relatively concentrated. With the continuous expansion of industrial robot application scenarios, the increase in domestic demand for industrial robots and the promotion of a series of policies such as "Made in China 2025" and smart logistics, Shanghai is gathering independent Research and development of OMV equipment and related intelligent technical equipment R&D, design, production, installation, commissioning and after-sales service. Its products are widely used in fields such as smart parking, national defense and military industry, rail transit, nuclear power inspection, logistics and warehousing, and modern digital factories.

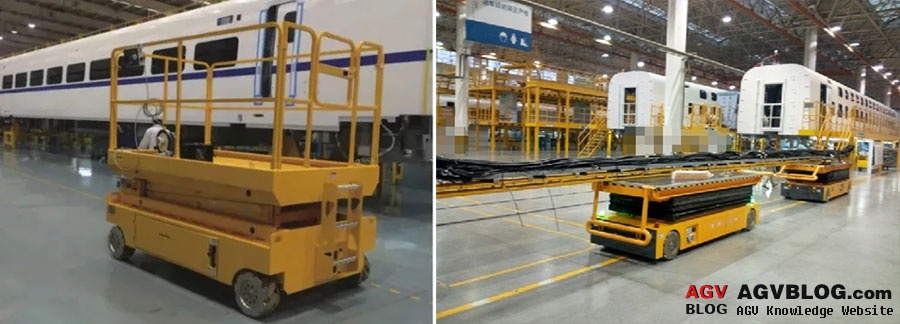

Convergence OMV (AGV assembly vehicle ) has been applied in:1. Rail transit:Omnidirectional mobile climbing operation vehicle: It can carry people and inspect equipment, check and repair the top of the vehicle, and the drift of any position improves the flexibility of the inspection vehicle. The lifting and moving of the platform increases the effective working space.OMV railway depot maintenance equipment: change the traditional maintenance mode, improve the degree of automatic maintenance, keep synchronization through laser ranging, unique communication technology, without any connection medium, truly independent dual-car linkage and synchronous control.Subway inspection and repair assembly car: high-speed rail small parts precision assembly car, specially designed for the inspection and repair of subway and high-speed railway car bottom parts, with a lifting platform that can freely and conveniently shuttle to the bottom of the vehicle, and accurately and efficiently disassemble and assemble the heavy components at the bottom of the vehicle.

2. Aerospace and military installation equipment: OMV omnidirectional transfer platform plus special tooling, as a special equipment for the transfer and docking of special heavy objects, is suitable for the docking and assembly of high-precision, heavy-duty, large-scale components, and can be fully automated. Improve work efficiency and ensure operational safety.

3. Precise docking of heavy-duty components:Application case: [State Grid Pinggao Electric] 15 tons of OMV loaded to achieve fast docking, safety and efficiency. Equipped with a precision jog remote control developed independently by Convergence, it is easy to realize the flange bolt hole docking, and it can easily carry the large-scale high-voltage resistant module of the State Grid 15 tons, which is 10 times more efficient than the traditional docking method. The flange ring with a diameter of 1 meter, a ring of 24 tight The bolts can be quickly connected in only 30 seconds, which is safe and efficient.4. Super-long parts transfer: The super-long parts are transported by heavy-load OMV, and the two-car linkage can be accurately connected.

5. Equipped with a large-scale robotic arm:1. Cooperate with a large-scale grinding manipulator and cooperate with the robotic grinding system to automatically polish the blades according to system instructions; an all-round mobile automation platform, which includes an intelligent control system, can realize the transfer and transfer of the grinding robotic arm, Complete unmanned automatic grinding operations, and solve the technical problems of manual grinding of workpieces in existing applications, such as large labor, low work efficiency, large errors, high production costs, and hidden health risks.2. Application case: Rocket body riveting robot, the bottom adopts the convergent OMV omnidirectional transfer platform: zero turning radius, side shift, can move in any direction without dead angle, special precision electric remote control can easily realize ±0.5mm high precision docking , Suitable for flexible assembly and polishing of rivets on the surface of aircraft, allowing the robot arm to move in any direction.

In today's rapid advancement of science and technology and economic globalization, modern logistics technology has been applied to various fields of economic life in countries around the world, and automated production is an effective way to reduce production and management costs. AGV assembly vehicles are the best way to achieve flexible manufacturing and flexible assembly. Best means of transportation. To meet the production model of multiple varieties and small batches, this will undoubtedly become the development direction of future production and manufacturing. Under such a model, AGV will become the main carrier of assembly, and the function of AGV in the flexible assembly industry will be fully utilized.