the concrete realization of AGVS in the paint industry

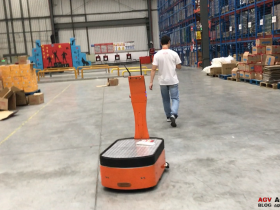

Mobile automatic handling material handling robot palletizing process include automatic, manual palletizing process, product storage processes and empty the tray out of the library processes, to achieve automatic material transport the whole process, and the warehouse seamless integration docking Management System WMS system . When the station needs materials, the logistics system issues the transportation request. After the AGV system receives the instruction, it issues the task to the nearest AGV. After the AGV receives the task to drive to the exact location of the platform, the fork lifts to remove the pallet goods and automatically moves to On the platform conveyor or the ground storage position requesting the material.

In order to connect the AGV to the conveyor safely, before the AGV enters the pickup station, it sends a request entry signal to the upper logistics system and receives the "allow entry" signal. At the same time, the AGV needs to be entered after the safety grating is released, that is, the AGV needs to communicate with the superior System and hardware interlock protection.

Automatic paint filling equipment, automatic paint packaging equipment, automatic palletizing equipment, warehouse three-dimensional warehouse, conveyor and rail shuttle, mobile handling robot (AGV) system, etc., through the interconnected industrial wired network, wireless network architecture, and through Warehouse management system WMS, warehouse control system WCS, manufacturing execution system MES, AGV scheduling system AMS realize the full life cycle control and quality traceability of the process from paint filling to storage and out of the warehouse.

In the AGV project in the paint industry, Meike shares as the integrator of core logistics equipment (mobile handling robot AGV system), providing mobile handling robot (AGV), automatic charging station, AGV management control workstation, control system software , AGV management The monitoring system, the hardware construction of some wired networks and wireless networks, and the interconnection and interconnection of field devices and the seamless integration with the warehouse management system WMS, warehouse control system WCS, and manufacturing execution system MES, etc. The materials involved in the production process such as automatic filling and product storage (empty pallet stacks, finished paint stacks, etc.) are automatically moved to achieve unmanned and electronic material handling and finished product storage.