the specific realization of AGVS in the home manufacturing industry

Faced with the current shortage of labor in the external market in the home manufacturing industry, shortage of labor, high employee turnover rate, high labor costs, and continuous low labor productivity, in order to improve the comprehensive efficiency of the home manufacturing industry, minimize the number of labor and reduce man-made The influence of factors on costs will support the realization of future mass customization production methods (MC). In the above-mentioned promotion of home manufacturing automation (FA) projects, the WMS system will be implemented in three business units in conjunction with the material management and distribution in the manufacturing process.

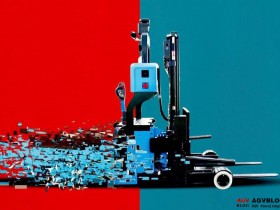

Automated logistics projects need to independently implement various functions of warehousing management: receipt, inventory at the correct location, inventory management, order processing, sorting and distribution control, and need to be efficiently integrated with logistics equipment such as automated three-dimensional library and AGV . It is not just managing logistics projects in the traditional sense, but the entire factory is managed by WMS through automated logistics projects. The factory is regarded as a large system and managed by logistics equipment such as automated three-dimensional warehouses and AGVs.

The automated logistics project will focus on the optimization and effective management of warehousing execution, while extending to transportation and distribution plans, and information exchange with upstream and downstream supplier customers, thereby effectively improving the warehouse execution efficiency of warehousing enterprises, distribution centers and production enterprises. And productivity, reduce costs, and improve the satisfaction of corporate customers, thereby enhancing the company's core competitiveness.

1. Timely data collection, precise process management, fully automated intelligent guidance, improve work efficiency;

2. Through AGV / RGV / STV to realize the automatic transportation of materials in the project area;

3. Realize precise storage location management and comprehensive status monitoring through automated three-dimensional warehouse, and make full use of limited warehouse space;

4. Materials are put on and off shelves, fully intelligent automatic allocation of positions to avoid human error;

5. Real-time control of inventory situation, reasonable maintenance and control of enterprise inventory.