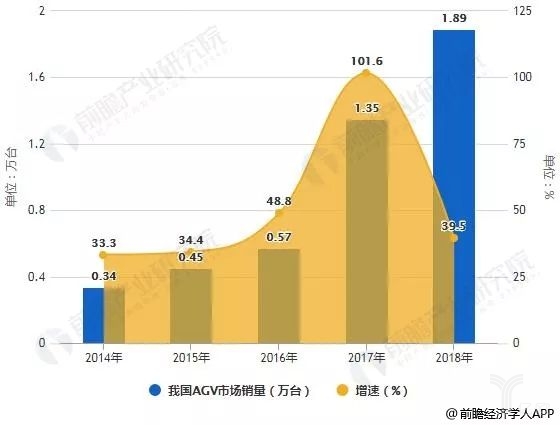

In the past five years, the average annual growth rate of logistics robots has exceeded 20%. In 2018, the market size of AGVs was nearly 19,000 units. Then, as e-commerce giants and express delivery companies such as JD.com, Amazon, Alibaba, Shentong, and SF Express have also significantly increased their picking robots, AGVs, and unmanned warehouses, smart logistics has become the general trend of the logistics industry. As an important technical equipment necessary to promote the development of smart logistics, logistics robots are showing vitality with the help of the development of smart logistics.

Multi-scenario and small-scale logistics robots

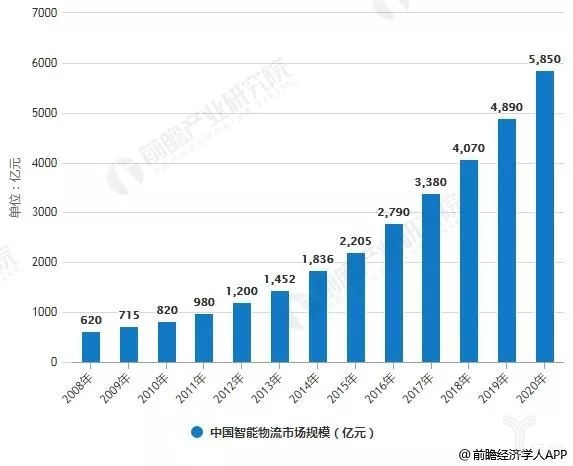

China's economy has been growing at a rapid rate for decades. With the development of manufacturing and service industries, the logistics industry has also kept pace. The "Analysis Report" statistics show that the scale of China's intelligent logistics market in 2008 was only 62 billion yuan. The scale of China's intelligent logistics market exceeded 10 billion yuan in 2012. Since then, the scale of China's smart logistics market has shown a rapid growth. As of 2017, the scale of China's intelligent logistics market has increased to 338 billion yuan. According to preliminary estimates, the scale of China's intelligent logistics market will exceed 400 billion yuan in 2018, reaching about 407 billion yuan. And predict that the scale of China's intelligent logistics market will reach 585 billion yuan in 2020.

In terms of AGV market sales, in 2014 China's AGV market sales were 0.34 million units, a year-on-year increase of 33.3%. In 2015, the sales volume of China's AGV market reached 4,500 units, a year-on-year increase of 34.4%. As of 2017, the sales volume of China's AGV market has increased to 13,500 units, a year-on-year increase of 101.6%. According to preliminary estimates, the sales volume of China's AGV market reached about 18,900 units in 2018, a year-on-year increase of 39.5%.

Statistics and Forecast of China's Intelligent Logistics Market Scale from 2008 to 2020

China's AGV market sales statistics and growth forecast from 2014 to 2018

In this huge market share, the three most basic steps of storage, handling, and sorting occupy a lot of time, money and labor costs. For reducing logistics costs, "machine substitution" has become a hope for everyone.

At present, machine substitution is spreading on a large scale worldwide, and the spreading market covers industrial, agricultural, medical, commercial applications, etc., and the market prospect is immeasurable. How to achieve automation and how to reduce logistics costs through logistics robots are the most urgent needs of many enterprises.

In the field of logistics, many companies are using lean and flexible production to use AGV (Automatic Guided Transport Vehicle) for material transportation, but because AGV is relatively low in intelligence, the operating system is relatively rigid, and can only obey simple programming Commands and equipment are prone to interruptions when they are updated, they are prone to failures when they encounter static or dynamic obstacles during transportation, and it is difficult to run complex, tedious, and intelligent instructions. Therefore, they can be used in a dynamic production environment. Only mobile handling robots can meet the needs of people.

Since smart logistics has gradually been recognized by the market, more and more companies have poured into it, trying to take a share in this 100 billion market, which is why more and more intelligent logistics robots appear in people's vision, such as JD.com Unmanned logistics robot, rookie logistics fast warehouse robot, etc.

The logistics robot market faces the characteristics of large market demand and large scale. According to industry analysts, logistics robots will have small-scale outbreaks in multiple scenarios in 2019, and the real big outbreak will be in 2020.

Although AGV and KIVA warehouse logistics robots help people solve many logistics scenarios, a large part still needs to be solved by autonomous mobile robots.

Because logistics robots have high technical barriers in core technologies such as high-precision parts and intelligent algorithms, the product application scenarios of logistics robots in China are still limited, mainly based on e-commerce logistics. In addition, there is no one in the logistics robot industry. With a complete and unified national standard system, the development of logistics robots in China is still in its infancy. "Technology + Policy" brings good development

"Technology + Policy" brings good development

From the perspective of China's robot products, there are three major categories of robots leading the world. One is that China's industrial robots account for more than a quarter of the global industrial robot market. China has been rated as the world's largest application market for six consecutive years. The second is the service robot; the third is the special robot.

With the gradual landing of the R & D achievements of China's robot core components, some core technologies have achieved large-scale products. More and more enterprises are gradually entering the field of robot manufacturing, so it is imperative to improve the standard system, improve the testing and certification, standardize the market system, and promote fair competition.

China attaches great importance to intelligent manufacturing during the "Thirteenth Five-Year Plan", and has implemented a number of policies to support it.

The "Guiding Opinions on Promoting the Development of the Industrial Robot Industry" was issued in February 2013. It is planned that by 2020, the number of robots used per 10,000 employees will reach more than 100.

In May 2015, "Made in China 2025" was introduced, taking industrial robots as the direction of intelligent development.

In April 2016, the "Robot Industry Development Plan" (2016-2020) was promulgated to vigorously develop key parts and components of robots, and develop common key technologies for robots.

In June 2017, the Ministry of Industry and Information Technology led the "Warehouse Robot and Intelligent Industry Alliance" to be formally established.

In addition, "Several Opinions of the State Council on Promoting the Development of the Express Delivery Industry", "Opinions on the Implementation of" Internet + "Efficient Logistics", "Thirteenth Five-Year Plan for the Development of Express Delivery Industry", "State Post Office on Accelerating the Supply Side of the Postal Industry Policy documents such as the Opinions on Structural Reform have also been issued.

These policies undoubtedly indicate that logistics companies should accelerate the promotion and application of information technologies such as cloud computing, big data, and the Internet of Things; increase data information integration applications, and promote the integrated development of logistics business platforms;

These policy documents are an important manifestation of the state's efforts to encourage logistics companies to actively adopt advanced technologies and equipment such as robots, drones, and unmanned vehicles, to realize automatic distribution and rapid transfer of express shipments, and to comprehensively improve the operational efficiency of warehousing, transportation, and distribution.

The battle for future competition is imminent

The logistics robot market is a big blue ocean. Today, using robots to reduce labor costs is a well-known thing. Therefore, major e-commerce and logistics companies are accelerating the popularity of logistics robot applications.

In 2019, driven by the rapid development of China's e-commerce industry, the freight volume and express delivery volume of the logistics industry are still expected to maintain steady growth, bringing huge market demand for logistics robots. Therefore, it has also urged the investment and financing processes of biological flow robots to continue to intensify. Many robot manufacturers or technology companies have obtained a large number of investments in the angel round, Pre-A round, A round, A + round. These investments are all robots. Manufacturers have injected the blood of development, and many logistics robot manufacturers go hand in hand, and the future industry war is about to begin.

For example, Alibaba recently acquired Shentong, and invested in Zhongtong and Yuantong; SF adopted the industrial robot sorting method; JD invested in the innovative robot layout of the road; Megsee Technology acquired Iris robots; Hechuang, Songhe, and Shenzhen Chuang invested in Stander robots ; Midea's launch strategy states that it will become "the world's leading technology group for consumer appliances, HVAC, robots and automation systems, and intelligent supply chain (logistics)"; Suning's active "scenario Internet + intelligent supply chain" involves no one Storage, unmanned vehicles, AGV robots, etc.

Logistics robots have poured into many competitors. In 2019, this competitive trend is bound to lead to the development of more sub-sectors.

In 2018, the development of logistics robots AGV and KIVA is relatively mature, but due to the limitations of application scenarios, progress has also stalled. However, as an emerging AMR (autonomous mobile robot), many companies have seen its application potential and future development. It is bound to help the birth of leading enterprises in the industry.

![[Depth] The rise of Chinese warehousing robot companies](http://www.agvblog.com/wp-content/themes/begin/thumbnail.php?src=http://www.agvblog.com/wp-content/uploads/2020/09/20200904102907-f2f5e.jpeg&w=280&h=210&a=&zc=1)