In a warehouse in Tianjin Fengshu, on a 9-meter high three-story loft shelf, multiple container-to-human robots are busy running, carrying the containers lightly and agilely back and forth between the storage area and the station, high speed Complete the storage and sorting of beauty products. This is the industry's first multi-layer container to human robot solution landing application, compared with the same area of manual warehouse, the efficiency is improved by 2.5 times.

As warehousing robots completely subvert the manual picking mode of traditional warehouses, and achieve a breakthrough in picking efficiency of more than 2 times, more and more companies are beginning to seek suitable warehousing robot solutions to achieve intelligent upgrading of warehouses. This vigorous market demand has spawned a variety of warehousing robots. "Container to human" robots have been a hot spot in recent years.

"Cargo box (material box)" is a common container form in logistics. The traditional automated equipment for handling material boxes has a high inventory utilization rate and high efficiency of storage, but it is generally expensive and lacks flexibility. The construction period is "year". Calculation, and if one of them is broken, the business may be shut down. Faced with this market pain point, many manufacturers have launched hopper robots in order to use the robot's flexible features to solve the rigidity of traditional hopper equipment.

Even so, the mainstream automation solutions on the market in the past still have their own emphasis, and it is difficult to meet all the needs of high storage capacity, high efficiency, high cost performance and high flexibility at the same time. In front of all enterprises planning to deploy warehousing automation, it is still a tangled choice of "fish and bear paw".

Until April 2019, Jizhijia unveiled a new generation of container-to-human storage robot system RoboShuttle® at the LogiMAT China exhibition and launched a three-dimensional multi-floor container robot storage and picking solution , ending this "everything has been difficult since ancient times" The situation! The solution uses the new Jizhijia C200S single-box robot. Through technological innovation and ingenuity, the first multi-dimensional space in the warehouse is realized in the robot solution, so that the flexible and efficient logistics robot system finally has the ability to The dense storage capacity of the multi-layer shuttle car is comparable to that, and the price is only half of the extra wear under the condition of achieving the same storage capacity and picking efficiency, and the cost performance is better.

This is the industry's first "four-in-one" innovative solution, which provides enterprises with a new set of automated deployment ideas. As soon as the system was released, it gained wide attention, and many manufacturers followed up with the layout of multi-floor storage and picking solutions.

After the first multi-floor storage and sorting solution exploded in the industry, in April this year, Jizhijia once again expanded the RoboShuttle® product line and launched a heavy attack in the field of container robots, releasing the world's first double-extended, narrow laneway, wide three-dimensional coverage The box-to-human robot C200M has created the AMR solution with the strongest single-layer storage capability to date .

According to the report of Interact Analysis, a global market research organization, Jizhijia ranks first in the world in the global AMR market share. The company has deployed more than 10,000 AMR robots around the world, serving nearly 300 global customers including Nike, Decathlon, Wal-Mart, and Suning, including more than 40 Fortune 500 companies, leading the industry in commercial scale.

R & D layout of products from box to person around customer pain points

Since the company was founded in 2015 and released the first domestic commercial goods-to-person picking system, it has continuously carried out technological innovation and product development around customer pain points, and rapidly expanded its product line to help the industry and enterprises break through existing bottlenecks.

Liu Kai, co-founder of Jizhijia and vice president of sorting and intelligent warehouse products, revealed to reporters: "Jizhijia made in-depth thinking and product layout on the form of containers to people as early as 2016. Our research and development ideas are in On the premise of maintaining a high level of traditional automation equipment for inventory utilization and storage efficiency, through the use of robots to introduce flexibility and high cost performance, the Jizhi RoboShuttle® system came into being. "

RoboShuttle® is a new-generation storage robot system that adopts the container-to-human approach, including robots and solutions such as single-box robots and double-extension robots. It is an innovative achievement in which Zhijia strives to improve the storage capacity of robot solutions and further optimize the picking efficiency.

"C200S and C200M are two adaptation solutions launched by the Jizhi RoboShuttle® system for different scenarios. C200S is suitable for multi-layer stereo storage solutions, and C200M is suitable for single-layer storage solutions."

Jizhijia cargo box to human robot layout ideas

RoboShuttle®'s multi-layer stereo storage solution (C200S robot)

Prior to RoboShuttle®, most robot solutions were limited to single floors, and the high-rise space of the warehouse was not fully utilized. Jizhijia's three-dimensional multi-floor robot solution enables logistics robots to be directly deployed in customers' existing attic for the first time , allowing enterprises to realize low-cost, high-density, and highly flexible storage without modification, while maintaining high storage of traditional automation equipment Density and high efficiency are unprecedented technological breakthroughs and innovations.

The C200S single-box robot used in this solution is smart, lightweight, and can be quickly walked on ordinary multi-storey attic shelves, stable and without obvious noise. The box picking action is simple and efficient, the work station layout takes up a small area (more work stations can be deployed in the same warehouse area, and the whole warehouse has a strong throughput capacity). Ladder to maximize the efficiency of picking people. It has been verified by practice that this solution is by far the most efficient AMR solution for picking.

The advantages of RoboShuttle® multi-layer stereo storage solution also include:

● Efficient: can increase the picking efficiency by 2 to 3 times on average;

● Short investment return cycle: the investment return cycle is 1 to 3 years;

● Flexibility: The number of robots can be flexibly increased or decreased according to customer needs, and the customer's site transformation is small; when the business peak exceeds the throughput capacity of the robot warehouse, it can be seamlessly switched to the manual warehouse mode;

● Customization: The single-layer or multi-layer attic shelves can be flexibly designed according to the height of the customer's warehouse, up to four layers, with strong adaptability.

The innovative success of Jizhijia's multi-layer storage solution has been highly recognized by international industry experts. The system won the German IFOY Intralogistics Certificate of the Global Industry Authority Award in February 2020. It is the only award-winning AMR company in the world, marking the world-class honor of AMR.

RoboShuttle® single-layer high-density storage solution (C200M robot)

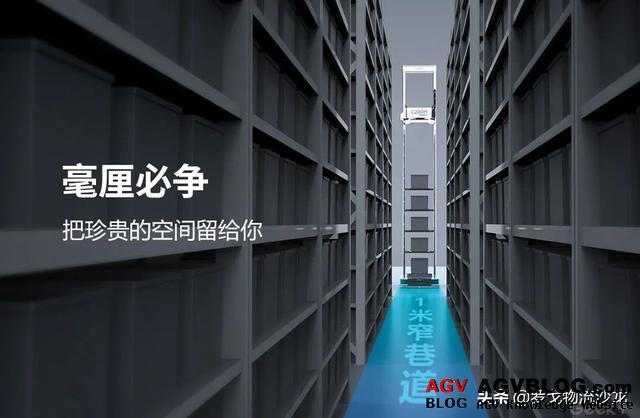

Jizhijia's single-layer high-density storage solution uses a double-extended, narrow aisle, ultra-wide three-dimensional covered container to human robot C200M, to achieve the AMR solution with the strongest single-layer storage capacity to date. The C200M innovatively uses a 1.4-meter double-extension design. The robot can complete the deep access of two rows of containers on one side of the shelf. The overall aisle area in the warehouse area can save up to 50% and reduce warehouse rental costs.

In addition, C200M also refreshed the effective storage range of the three-dimensional space of the robot warehouse. The robot's cargo box access range is as low as 0.215 meters and up to 5 meters, maximizing the three-dimensional storage space. On the basis of wider three-dimensional coverage, the C200M only needs 1 meter narrow roadway, further compressing the channel area required for robot operation and increasing storage space. By making full use of the horizontal area and vertical space, the storage capacity of the C200M robot warehouse is 2.5 times higher than that of the manual warehouse.

The door frame of C200M adopts modular design, and the height can be customized according to customer needs. Modular components also make installation and deployment more convenient, can be assembled on site, no lifting is required, and transportation and loading are easier. C200M can be connected to a variety of automation equipment such as conveyor lines and other robots, which is convenient for integration and customized project deployment, and has a short construction period and fast online speed, which is convenient for enterprises to quickly realize flexible and intelligent upgrades.

"Only technology that really creates customer revenue can be brought to market"

Regarding the layout strategy of the RoboShuttle® series, Liu Kai said: "In the early stage of the design, Jizhijia has compared a variety of multi-layer picking solutions: traditional shuttle, Miniload, Autostore, multi-layer shelf to people, multi-layer multi-carton to people, Multi-layer single boxes to people, etc., carried out a full range of detailed analysis, simulation and testing from various aspects such as storage capacity, picking efficiency, return on investment, and applicability of existing warehouses, and finally selected the best performance, The most suitable single box robot. "

It is understood that the actual storage capacity of most multi-box robot solutions on the market at that time was not ideal. Although the 4-meter shelf is higher than the 2.5-meter shelf of the manual warehouse, it seems to increase the storage space. However, because the robot needs more space for picking up goods, the density of the material box is lower, and a wider channel is required. The actual storage capacity is only equivalent to that of the manual warehouse. In addition, multi-box robots are too heavy, custom steel platforms are expensive to build and costly to deploy, so they are not suitable for multi-floor operating environments. According to reports, the project of a single-extension multi-box robot was stopped because it could not properly handle the above problems.

Commercial landing confirms product value

The Jizhijia RoboShuttle system was built and put into use in the Fengshu warehouse in Tianjin last October, serving a beauty client of the Jizhijia RaaS business. This is the industry's first multi-layer cargo container to human robot solution landing application. Compared with the manual warehouse of the same area, the efficiency is improved by 2.5 times.

At the same time, RoboShuttle quickly and successfully went to sea and landed in a large French fresh food e-commerce giant project. Recently, the actual effect of the RoboShuttle system has been further fully verified in the e-commerce warehouse project of a well-known clothing brand, and the test results show that the efficiency of RoboShuttle is three times that of the products of the friends.

The R & D and expansion of Jizhijia's "container to human" series fully reflects Jizhijia's understanding and persistence of logistics robot solutions. In order to meet the needs of enterprises to upgrade intelligently in different scenarios, solve bottlenecks and pain points, Jizhijia has created a comprehensive logistics robot product line and solutions, including picking, sorting, handling, smart forklifts, smart warehouses and smart factories. A series of product lines covering the two major scenarios of warehouse and manufacturing, realize the whole process from production supply chain to consumer supply chain, and can provide customers in different industries with the most suitable solutions for different scene needs.

Based on the commercial landing scale and successful project experience of over 10,000 units deployed worldwide, and industry leaders such as Intel, Microsoft, BOSCH, etc., also as ecological partners, Jizhijia's solutions have always stood the market verification, creating true and visible customers Business returns.

This article is the author's personal opinion and does not represent the logistics salon's position