Recently, in a warehouse on the outskirts of Berlin, a newly added robot has attracted media attention. This robot for sorting items is "a major advancement in the ability of artificial intelligence and machines to work with humans." A demo video of a working robot shows that the robot puts objects of different shapes in different containers. "When millions of products are circulated in warehouses operated by Amazon, Wal-Mart and other retailers, low-wage workers must comb through piles of debris from clothes, shoes to electronic devices over and over again, so that each All items can be packed and shipped.

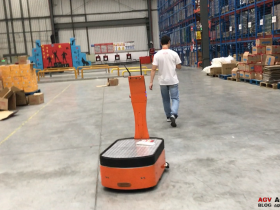

Until now, the machine has not really qualified for the job. An expert opened the door to IEEE Spectrum and pointed out this point: With all the activities related to logistics automation, there are two types of real automation requirements in the warehouse: Things done by hand. The expert cited is Peter Abil, the founder, president and chief scientist of Covariance. He asserted that the leg part has been solved by a transmission system, mobile retrieval system and other functional robots, but "the problem It ’s the hand part. ”When it comes to the hand part, he means“ how to handle manual work in the warehouse more efficiently. "Join Covariant. In the secret of picking solutions, most accessories are simple, predictable hardware.

Evan Ackerman listed them in the IEEE Spectrum magazine: ready-made industrial arms, suction grippers, and two-dimensional camera systems. The magic is in a very large neural network. It translates into a cost-effective solution for customers. how could be? Abil said, "We cannot build a dedicated network, it must be a single network that can handle any type of inventory and any type of picking station." Abil said that this covariant solution is called covariance The brain, which has something in common with the human brain, is that "a single neural network can do everything." If robots in manufacturing cannot think independently, then they can only reach a small part of their potential; and what if robots can accomplish tasks other than preprogrammed in a controlled environment? James Vincent talked about the importance of the covariant robot in the overall picture of the picking robot on The Verge website: "The robot itself does not look special, but what makes it different is its eyes and brain. With the help of a six-lens camera array and machine learning algorithms, it can grab and pack things that other robots will confuse. Think about the situation of a pre-covariant brain. In this case, you have a traditional system that advances It is designed to classify everything and try to identify all the content in the catalog.

Now let ’s imagine using covariance to pursue a vision of having a lot of inventory in a fast-moving and always changing warehouse. Asked about training to identify new categories of objects, Abil said in an interview with IEEE Spectrum: "Our system has almost no lens adaptability, which means that there is no need for us to do anything when the system is running, when it cannot be successfully identified It will update its understanding of the scene on its own and try some new things. "Obviously, warehouse leaders will be interested in a robotic arm that can complete as much picking work as possible in a timely and accurate manner. Karen Hao said that this technology must be flexible to adapt to a variety of product shapes and sizes in changing directions. A traditional robotic arm can be programmed to perform the same precise action again and again, but once it encounters any deviation, it will fail.

The California-based robotics company issued a press release announcing that Covariant has partnered with a warehouse logistics technology company, Knapp, to put Obeta's workstations into production. Knapp is engaged in the technical business of medical, textile, fashion and retail facilities. Knapp, based in Austria, was very interested in the artificial intelligence manipulators they could use. Knapp ’s vice president of innovation, Peter Puchewin, said: “We have never seen this quality of artificial intelligence before.” Hao said that through this collaboration, “Knapp will distribute support covariance to customer warehouses in the next few years Robot. "What next? Hao said: "In addition to picking, we also hope that it will eventually cover all aspects of warehouse management, from unloading trucks to packaging boxes to sorting shelves. We also envisage expanding our business to other areas and industries outside the warehouse."