Click on the "mechanical design pass" above to follow us and learn a mechanical design related knowledge point every day

What is AGV

(Automated Guided Vehicle, abbreviated as AGV), usually also called AGV car. It refers to a transport vehicle equipped with automatic guidance devices such as electromagnetic or optical, which can drive along a prescribed guidance path, and has safety protection and various transfer functions In industrial applications, trucks that do not require drivers are powered by rechargeable batteries. AGV has a history of 50 years since its invention. With the expansion of the application field, its types and forms have become diverse. AGVs are often divided into the following types according to the navigation method during AGV automatic driving: electromagnetic induction guided AGV, laser guided AGV, visual guided AGV, in addition to ferromagnetic gyro inertial guided AGV, optical guided AGV and other forms of AGV.

1. Electromagnetic induction guided AGV

Electromagnetic induction guidance is generally to bury wires on the ground along a predetermined travel path. When high-frequency current flows through the wire, an electromagnetic field is generated around the wire. Two electromagnetic sensors are installed symmetrically on the AGV. The difference in the intensity of the electromagnetic signal can reflect the degree to which the AGV deviates from the path. The AGV's automatic control system controls the vehicle's steering based on this deviation, and continuous dynamic closed-loop control can ensure the AGV's stable automatic tracking of the set path. This electromagnetic induction guided navigation method is currently used on most commercial AGVs, especially for large and medium-sized AGVs.

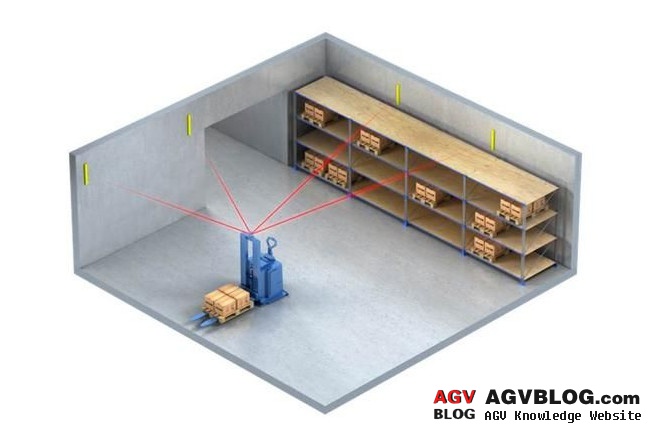

2. Laser-guided AGV

Laser navigation AGV technical advantages:

The AGV is equipped with a rotatable laser scanner, and the laser positioning mark of a highly reflective reflective plate is installed on the wall or pillar along the running path. The AGV relies on the laser scanner to emit a laser beam, and then receives reflection from the surrounding positioning mark The returned laser beam, the on-board computer calculates the current position of the vehicle and the direction of movement, and corrects the orientation by comparing with the built-in digital map, so as to realize automatic transportation. At present, the application of this kind of AGV is becoming more and more common. And according to the same guiding principle, if the laser scanner is replaced with an infrared transmitter or an ultrasonic transmitter, the laser-guided AGV can become an infrared-guided AGV and an ultrasonic-guided AGV.

3. Vision-guided AGV

The vision-guided AGV is a rapidly developing and mature AGV. This kind of AGV is equipped with a CCD camera and a sensor, and an image database of the surrounding environment of the AGV's driving path is set in the on-board computer. During the AGV driving process, the camera dynamically acquires image information of the surrounding environment of the vehicle and compares it with the image database to determine the current position and make a decision on the next driving. This AGV does not require any physical path to be set manually, so it has the best guidance flexibility in theory. With the rapid development of computer image acquisition, storage and processing technology, this AGV is becoming more and more practical.

The advantages of AGV car

1. High degree of automation

Controlled by computer, electric control equipment, magnetic induction sensor, laser reflector, etc. When auxiliary materials are needed in a certain part of the workshop, the staff enters the relevant information into the computer terminal, the computer terminal then sends the information to the central control room, and the professional technicians issue instructions to the computer. With the cooperation of the electronic control equipment, this The instruction was finally accepted and executed by AGV-to send the auxiliary materials to the corresponding location. AGV car is an essential tool for flexible manufacturing and automatic storage.

2. Charging automation

When the power of the AGV car is about to run out, it will send a request command to the system to request charging (general technicians will set a value in advance), and automatically "queue" the charging place after the system allows it. In addition, the battery life of the AGV car is very long (more than 2 years), and it can work about 4h every 15 minutes of charging.

3. Beautiful, improve the viewing degree, thereby enhancing the corporate image

4. Convenient, reduce the floor space

The AGV car in the production workshop can shuttle back and forth in each workshop. AGV trolleys will gradually replace manual material handling.

AGV car application

At present, AGV cars have been widely used in aerospace, home appliances, commerce, food, medicine, heavy industry, logistics, manufacturing and other industries, and are also one of the indispensable equipment for modern logistics loading and unloading goods.

1. Warehousing

Warehousing is the earliest application of AGV. In 1954, the world's first AGV was put into operation in the warehouse of Mercury Motor Freight in South Carolina, the United States, which was used to realize the automatic handling of goods in and out of the warehouse. At present, there are about 20,000 various AGVs in the world operating in 2,100 large and small warehouses. In the three-dimensional warehouse of the development zone that Haier Group put into operation in 2000, 9 AGVs formed a flexible automatic handling system in the warehouse, which successfully completed the handling of 23,400 goods and parts in and out of the warehouse every day.

2. Manufacturing

AGV shows its talents in the production line of the manufacturing industry, and completes the material handling tasks efficiently, accurately and flexibly. In addition, a flexible logistics handling system can be composed of multiple AGVs. The handling route can be adjusted in time with the adjustment of the production process, so that more than a dozen products can be manufactured on one production line, which greatly improves the flexibility of production and the competitiveness of enterprises. In 1974, in order to improve the flexibility of the transportation system, the Swedish Volvo Kalmar car assembly plant adopted an automatic car assembly line based on AGVS as a vehicle. This assembly line consists of multiple AGVSs that can load car bodies. After using this assembly line, assembly time is reduced By 20%, assembly failures were reduced by 39%, investment recovery time was reduced by 57%, and labor was reduced by 5%. At present, AGV has been widely used in the manufacturing and assembly lines of major automobile factories in the world, such as GM, Toyota, Chrysler, Volkswagen and other automobile factories.

In recent years, as the basic transportation tool of CIMS, the application of AGV has penetrated into many industries such as mechanical processing, home appliance production, microelectronics manufacturing, and cigarettes. The production and processing field has become the most widely used field of AGV.

3. Post office, library, port terminal and airport

In the post office, library, terminal and airport, the delivery of goods has the characteristics of large changes in operation volume, strong dynamics, frequent adjustment of the operation process, and a single handling operation process. The characteristics can meet the handling requirements of the above-mentioned occasions. Sweden started using AGV at the Stockholm Post Office in 1983, Tokyo Tama Post Office in 1988 in Japan, and China at the Shanghai Post Hub in 1990 to complete the handling of postal products. In the port of Rotterdam, the Netherlands, 50 AGVs called "yard tractors" complete the repetitive work of shipping containers from the side of the ship to a warehouse a few hundred yards away.

4. Tobacco, medicine, food, chemical industry

For the tobacco, medicine, food, chemical and other industries that have special requirements for clean, safe, and non-discharge pollution in handling operations, the application of AGV has also been paid attention to. In many domestic cigarette companies, such as Qingdao Yizhong Group, Yuxi Hongta Group, Honghe Cigarette Factory and Huaiyin Cigarette Factory, laser-guided AGV is used to complete the handling of pallet goods.

5. Hazardous locations and special industries

In the military, based on AGV's automatic driving, it integrates other detection and disassembly equipment, which can be used in battlefield demining and position reconnaissance. Automatic reconnaissance vehicle. In steel mills, AGVs are used for furnace charge transportation, reducing the labor intensity of workers. In nuclear power plants and places that use nuclear radiation for fresh storage, AGVs are used for the transportation of items, avoiding dangerous radiation. In film and film warehouses, AGV can accurately and reliably transport materials and semi-finished products in a dark environment.

In the next few years, AGV cars will appear in workshops in various industries. Compared with many domestic manufacturers who focus on AGV, Dongjin Technology AGV car has been applied to all walks of life and will strive to better serve customers' automation and intelligent development. As an automated unmanned handling equipment, AGV car can reduce the labor intensity and improve work efficiency. At the same time, it can accomplish some "impossible tasks" skillfully and quickly. For example: the assembly workshop of large equipment such as automobiles, aerospace, chemical industry, etc. . In this way, the AGV car has a place to use. No manual care is required. Using the AGV car can reduce labor burden.

Everyone is welcome to add in the comment section what you think is wrong or missing in the article, so that the next person who reads it will learn more. What you know is what everyone needs. . .

![[Depth] The rise of Chinese warehousing robot companies](http://www.agvblog.com/wp-content/themes/begin/thumbnail.php?src=http://www.agvblog.com/wp-content/uploads/2020/09/20200904102907-f2f5e.jpeg&w=280&h=210&a=&zc=1)