Make AGV Logistics more valuable: create five cores of value in AGV logistics automation. Based on Michelson's experience working with customers in the AGV industry and Industry 4.0 transformation, we identified five cores that can help companies successfully transform the “AGV Logistics” solution into real value and bottom line impact.

Make AGV logistics more valuable: the five cores of AGV logistics.

AGV logistics is a source of productivity gains

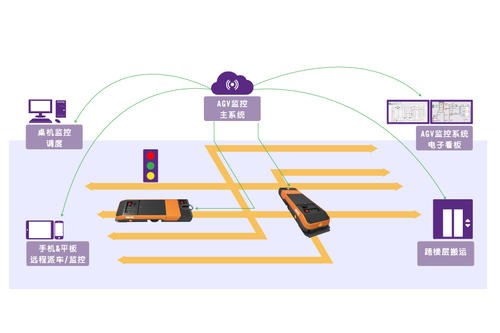

As cost pressures in various industries continue to increase, companies face the need to increase productivity by two to four percentage points per year. Based on years of AGV industry surveys, estimates made by Mikkeli have shown that advances in AGV logistics automation have unlocked the potential to create 5% to 15% efficiency gains that will not come from the application of a single solution. For example, through predictive maintenance or remote monitoring, a 10% to 30% reduction in switchboard downtime will greatly increase asset utilization, and saving manpower is another area of great potential. Digital management combined with advanced robotics and self-AGV vehicles can further automate operations and increase labor productivity by 20% to 30%. Advanced analysis of the fine-grained data of the real-time generated machining process is the root cause for more accurate and effective identification and resolution of process inefficiencies. In addition, the large demand for data from the forecasting process has greatly reduced the backlog of data and improved service levels.

AGV logistics is an evolution of the entire organization, not just the automation department

The automation department enables AGV logistics to drive implementation, so companies often first consider how to apply new solution applications to the automation department. But they should focus more on how the future will unfold, and consider this change from a value chain and business perspective. In short, with the new opportunities offered by digital, the “point of time” utilization will be greatly improved.

The development of AGV logistics needs to be led by senior management

Few companies have adopted a structured approach to implementing AGV logistics. Research shows that 16% of companies have a clear strategy, and 24% of companies have defined the development of AGV logistics. Even these planned companies tend to make one of two mistakes: they assign responsibility to people who only have employee functions, who do not have direct execution capabilities, or who will have the required responsibilities in the management hierarchy. Blame on people with too low a function.

The application of any kind of innovative technology will have a negative impact on the realization of change. Opening up AGV logistics also means taking risks, and the commitment to these risks cannot be delegated. Therefore, top management must have ownership and a procedural approach to promote the formation of values quickly and effectively. The direct involvement of senior staff helps determine the success of AGV logistics.

Choosing reliable AGV technology and providers is critical

First of all, technical solutions including AGV robots or advanced logistics analysis software are extremely easy to access and install. In fact, these tools have become a commodity in many cases. However, it combines technology and corresponding domain knowledge (for example, in value chain, maintenance, or process modeling) to produce behavior that provides value. In addition, the true implementation of these solutions often requires newly designed workflows and functions, both of which require large-scale transformations. Company leaders must carefully choose to build high-tech talent or work with high-end technology organizations.

AGV logistics requires a transformative and comprehensive approach to thinking

The transformation of the AGV logistics model is not just a process of improving maintenance, but taking the entire production site into consideration. For industrial AGV logistics development, companies will need to reorganize the entire value chain, apply a complete set of solutions, and develop a relatively clear plan to expand the entire AGV application network.

To achieve AGV logistics, you should keep in mind:

● Identify priorities and keep the pace smaller. Don't take the time to do too extensive analysis and planning, but you should amplify the impact, make targeted transformations, and learn at any time while progressing.

● Ability, most companies are eager to accelerate their development by implementing AGV logistics in the workshop, but the ability to improve can not keep up with the speed of change. Of course, the company can also seek help from AGV manufacturers like Microcli.

● Thinking patterns and behaviors. Past experience shows that the mentality and behavior of leaders and employees largely determine the failure or success of a company's transformation. Therefore, AGV logistics needs to penetrate the entire organization, and people need to truly accept the transformation that has already begun.

A successful digital revolution requires specific understanding and participation from every company, every manufacturing plant, or even every department. In order to make it easier to identify and prioritize transformations that are valuable to them, Microcree can develop targeted solutions for its own potential through on-site testing and comparison of changes made before and after the use of digital AGV logistics.