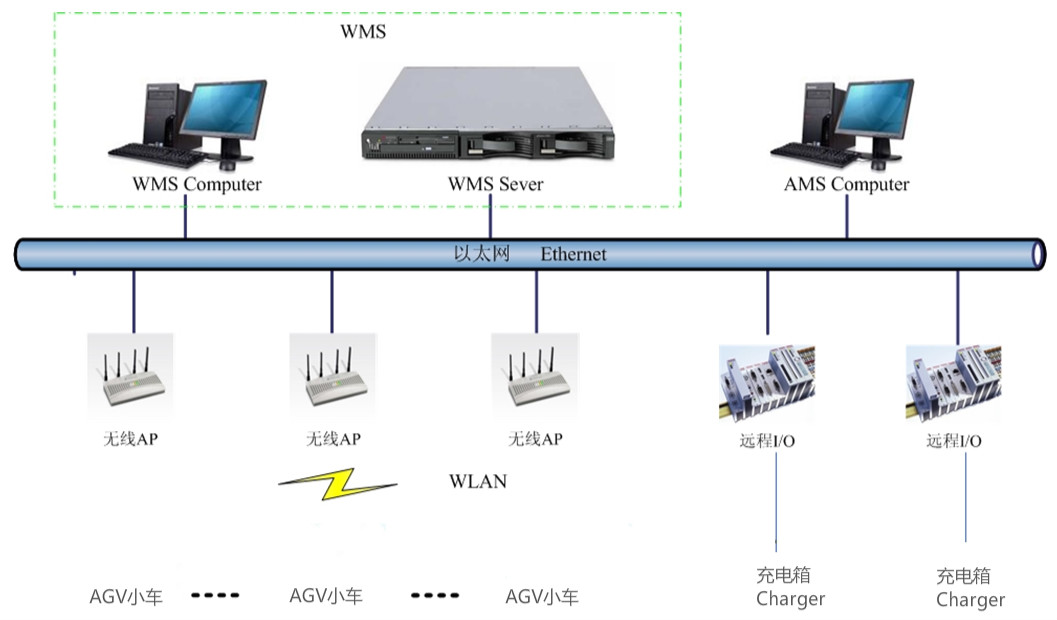

The AGV conveyor system consists of an AGV trolley, an AGV control system, an AGV charging system, and other auxiliary equipment. The AGV control system is mainly composed of AGV management and monitoring computer, NT8000, CWay8, AGV automatic scheduling software and other software, as well as wireless AP, positioning reflector, and integrated wiring. The AGV management monitoring computer communicates with the library logistics management system computer via an industrial Ethernet network. The AGV management monitoring computer communicates with the AGV trolley via the wireless LAN WLAN. The system structure is shown in the following figure:

AGV car system _meitu_1

Schematic-diagram-of-AGV-conveying-system

How does the AGV conveyor system realize the intelligentization of factory logistics?

1. Material delivery

The shop operator calls the required materials at the calling terminal, and the logistics management system automatically transfers the corresponding materials from the three-dimensional library, and the delivery system is sent to the specified AGV pick-up station. The library logistics management system sends a pickup request to the AGV monitoring management computer. The AGV monitoring management computer dispatches the nearest, idle AGV car to the corresponding pick-up station according to the request, and takes the material and sends it to the designated station. Finish the delivery of the goods.

2. Residual material return conveying

The operator calls the remaining material back to the library at the calling terminal. The logistics management system sends a reclaimed request to the AGV monitoring management computer. The AGV monitoring and management computer dispatches the AGV car with the closest distance and has just unloaded the goods to the corresponding pick-up station according to the request, and takes the surplus material and sends it to the remaining material recycling station. Complete the recycling of the remaining material. This task is compounded in the task of the outbound by scheduling optimization.

3. Turnover box recycling

The operator places the empty turnover box code on the empty turnover box platform and calls the empty turnover box back to the library at the calling terminal. The logistics management system sends a short tray request to the AGV monitoring management computer. The AGV monitoring and management computer dispatches the AGV car with the closest distance and has just unloaded the goods to the corresponding pick-up station according to the request, and takes the empty turnover box and sends it to the empty turnover box recycling station. Complete the empty totes recycling collection. This task is compounded in the task of the outbound by scheduling optimization.