At present, domestic homogenization competition is fierce and labor costs are high. Especially in the face of manufacturing enterprises, the main task is cost and quality. Therefore, the demand for various robots is becoming more and more urgent, and the use of AGV logistics robots is gradually becoming popular. It is used in all walks of life, such as: traditional production materials transportation, flexible assembly lines, processing lines, etc. The earliest application fields of AGV robots are mainly in the fields of automobile equipment, tobacco industry, pharmaceutical industry, chemical industry, locomotive high-speed rail industry, etc. The application of AGV in foreign countries is relatively early, so the large-scale AGV used in high-end manufacturing still relies mainly on imports. The domestic start is relatively late. The current products are mainly concentrated in the AGV small car and flat AGV.

Talking about the type and price of AGV robot

The price gap between AGV robots at home and abroad is very high, which depends on different AGV types. Common small AGVs such as: piggyback AGV, latent AGV, traction AGV, lift AGV, chain AGV, push-pull slide AGV, followed by There are also large AGV: forklift AGV, gantry AGV, flat type large tonnage traction AGV...

Then we may wish to compare the domestic and international AGV price factors and the future development direction: the price of AGV in a laser navigation forklift in Europe and America is about 1 million yuan, which is equivalent to the salary and welfare of four local workers in Europe. Social security, etc., also requires an ordinary forklift for about 5 years and 200,000 depreciation. The cost of AGV robots is equal to the wages of workers and the difficulty of management. This is the reason why AGV uses AGV in a large number of high-end manufacturing industries in Europe and America.

Although the AGV technology in Europe and America is mature and reliable, the single-machine load can range from 50 kg to 100 tons. Multiple AGVs can work seamlessly to achieve unmanned operation....but the price is from 1 million to tens of millions. The price and after-sales service costs are difficult for these AGV manufacturers in Europe and the United States to promote sales in general or pure processing industries in China and even Asia.

In China, South Korea and Japan and other Asian countries, the AGV has been developed for the purpose of targeted and simple production applications. The AGV is only used for handling. In the automatic navigation of AGV, it mainly uses simple tape guidance, eliminating complicated electronic maps and scheduling of upper and lower stations, etc., and miniaturizing the AGV to minimize the cost of AGV to meet the needs of ordinary manufacturing. Function, technology pursues simple and practical, and strives to allow users to recover investment costs in the shortest time. Such miniaturized AGVs are widely used in Asian countries.

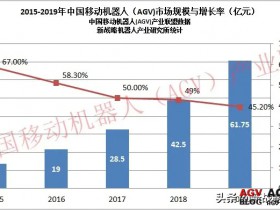

With the advancement of automated production in all walks of life in China, the demand for industrial robots is increasing. The era of economic development by relying on the demographic dividend advantage is gone forever. The only way for enterprises to improve their labor costs is to improve their effectiveness. Labor productivity, which is to increase the degree of production automation, AGV has a broad market as the most flexible automated transportation equipment. In recent years, some excellent enterprises in China have also adopted AGV robots on a large scale. However, most of the domestic AGV manufacturers generally lack innovation and technology upgrades, and even their own R&D team has not copied the Dongping West. The result is a high failure rate. Problems with short component life.