Design and pickup of AGV bevel gear

Comparing with other mechanical transmission, the gear transmission has the advantages of reliable performance and long lifetime, constant as realtime transmission, high efficiency of transmission, compact structure and wide scope of application of speed and power.

Stable transmission --- changeless realtime transmission rate, reducing shocking, vibration and noise as much as possible for better power transmission and stable moving.

High loading capability --- It’s required that under the light-weight and small-size condition, the gears must be highly strong and wearable, no failure like gear breaking off will occur within the scheduled usage period.

In the designing, manufacturing and scientific researching, it’s all for two basic requirements in profile curve, gear strength, manufacturing accuracy, processing methods and heat treatment technics, also the most important connection for processing and

meeting accuracy.

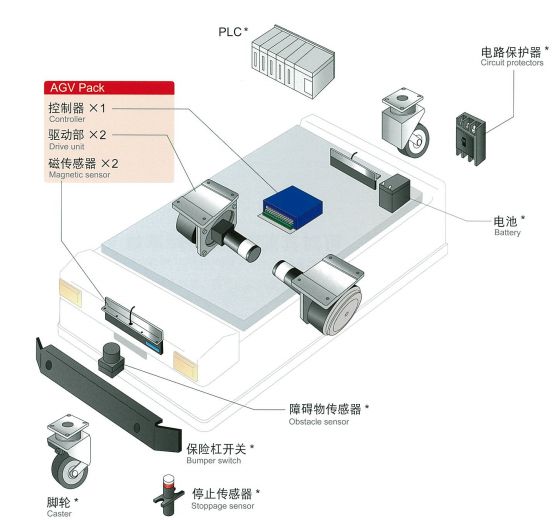

Below table 3-5 and 3-6 shows the standard bevel gear modulus m and confirmation of basic tooth profile.

Standard modulus

Bevel gear

Basic tooth profile of coniflex gear

Basic parameter

Tooth profile angle

Tooth addendum

Working depth of tooth

Tip clearance

Tooth root filet radius

Bevel gear

According to the design and structure, get standard modulus m=2.5 from table 3-5, then confirm data of basic tooth profile of coniflex gear size, tooth addendum =2.5

Working addendum`h`=5

Tip clearance c=0.5

Tooth root filet radius pf=0.75

Big-end reference circle diameter d=mz,get the number of teeth z=30

Tooth breadth b=0.3 ×R R is the conical spur get b=13.317

take b=14

Conical spur R and big-end reference circle diameter known, so the reference cone angle =57.65°

Calculate the transmission power of the two gears according to mesh formula to meet the requirement.