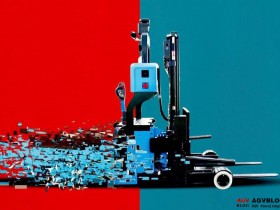

Lead: AGV handling robot system involves mechanical, electronic, optical, computer and other fields, widely used in modern smart logistics factories. The AGV handling robot is an intelligent material handling equipment. It has many advantages such as high automation, flexible application, safety and reliability, unmanned operation, simple construction and convenient maintenance. It is widely used in tires, garments, 3C, home appliances, automobile manufacturing, Tobacco, machinery and other industries. At the same time, AGV handling robots are also widely used in flexible production systems (FMS), flexible handling systems and automated warehouses. It is the key equipment of modern logistics system and has important significance for improving production automation and improving production efficiency.

The automatic guided vehicle system (hereinafter referred to as AGVS) is an unmanned automatic control system, mainly consisting of automatic guided vehicle (AGV), ground management system (VSM) guidance system, address coding system, through reading system, parking station, charging station. It consists of basic units such as peripheral equipment. Among them, the AGV handling robot is one of the main parts of the automatic guided vehicle system. The advantages of the AGV handling robot are: flexible transportation, flexible use, high transportation efficiency, energy saving, reliable system operation, and pollution-free operation to improve the working environment.

The AGV handling robot control system is its direct control hub that integrates motor system, sensor signal processing, drive control, positioning algorithms, electronic maps and wireless communications. The main function of the completion is to receive the control of the movement direction and movement speed of the AGV handling robot and the detection of obstacles during the movement of the AGV handling robot through the wireless communication system receiving the tasks of the main control unit or the on-board control unit or the operation buttons on the operation panel. , security alarm and status indication, and report its own status to the host computer through the wireless communication system (such as the current position of the AGV handling robot, current working status, current speed and direction, etc.).