For the precision grinding of the ring guide rail, the AGV trolley can circulate along a precise trajectory; how to provide power to the trolley so that the trolley can achieve high-speed and precise cyclic movement has always been an issue that engineers are considering.

The circulating conveying line is a good combination of ring guide rails and linear motors, which can achieve ultra-high circulating conveying efficiency and greatly shorten the production cycle.

01 Principle structure

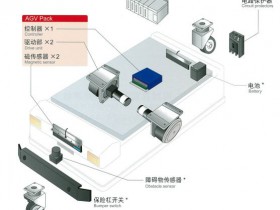

As shown in the figure below, the linear motor is not a normal linear motor, but a linear motor that can bend to make a circular motion and achieve closure. It can be called a toroidal linear motor; the stator is composed of coils and is fixed on the base of the equipment. Magnetic field; the mover is installed on the sliding seat and is a permanent magnet; the permanent magnet on the sliding seat is pushed by the magnetic field generated by the induction coil of the stator, and the sliding seat moves along the guide rail. The basic principle is similar to magnetic levitation; the mover on the sliding seat It is a permanent magnet and does not need power supply to generate a magnetic field, so there is no power cord, so the slide can do infinite loop motion:

Ring guide rail + linear motor = XTS ultra-efficient circulating assembly line

Mechanical Engineers (MechanicalEngineers)

The linear motor is located above the ring guide rail. The bottom of the trolley is equipped with rollers to cooperate with the ring guide rail; the upper part of the trolley is equipped with a mover, which cooperates with the stator of the linear motor to provide power.

Racetrack type ring rail + linear motor = XTS ultra-efficient circulating conveyor line

02 Advantages

The big advantage of the circulating pipeline is that each car is independently controlled, which is equivalent to an independent servo motor. The acceleration and deceleration curve of the car can be set through independent programming. Different cars can use different acceleration and deceleration curves; It is convenient to realize the buffer function in automatic production; if you need to change the process sequence, you only need to change the program setting through the software, without the need to modify and change the mechanical mechanism.

The core mechanical components of the whole system are the circular guide rail and sliding seat shown in the figure below, which can be made into a racetrack or rectangular shape.

XTS ultra-efficient circulating conveyor dedicated ring guide rail

Mechanical Engineers (MechanicalEngineers)

03 Application case

Compared with the circular filling system, the linear filling machine is more friendly in terms of project application, user use and maintenance. However, in some occasions where large machines cannot be used, the processing speed will be limited. Magnetic levitation ring guides can solve these problems well. With the same assembly line efficiency, it needs less space and is more compact, so that there are more options for supporting equipment. Just like the following filling line.