1. The meaning of RGV, AGV and IGV.

With the rise of intelligent manufacturing on a large scale around the world, the forthcoming fourth industrial revolution has also led to the rapid development of the intelligent manufacturing industry. As one of the core equipment of intelligent logistics, mobile handling robots have been developed in recent years. It has shown explosive growth. In addition to common AGVs, RGV and IGV are also an indispensable part of the automated logistics system.

The meaning of RGV, AGV and IGV

RGV: The full name is Rail Guided Vehicle, that is, "rail guided vehicle", also called "rail shuttle car". RGV is often used in three-dimensional warehouses with various high-density storage methods. The trolley channel can be designed as long as needed, and no other equipment is required to enter the roadway when handling and moving goods. It is fast and safe, which can effectively improve the operating efficiency of the warehouse system. .

AGV: The full name is Automated Guided Vehicle, which means "Automated Guided Vehicle". An AGV is a transport trolley equipped with electromagnetic, optical or other automatic guidance devices that can travel along a prescribed guidance path, with safety protection and various transfer functions.

IGV: The full name is Intelligent Guided Vehicle, that is, Intelligent Guided Vehicle. IGV is a new concept put forward in recent years. Compared with traditional AGV, IGV is more flexible, does not need to use any fixed markers to drive, and the route is flexible and changeable, and can be flexibly scheduled according to actual production needs.

RGV, AGV and IGV are all used to realize the automatic handling and reloading of materials, but in terms of automation and intelligence, RGV

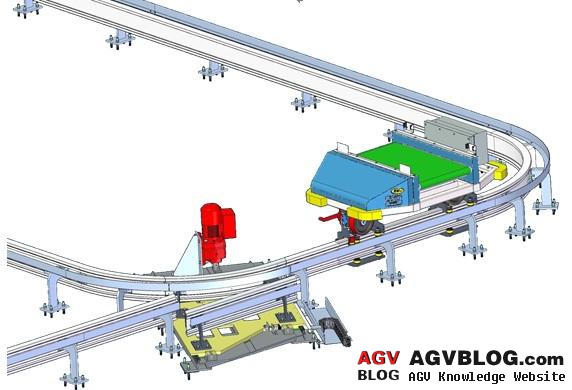

Because RGV travels on rails, its application is relatively simple. Commonly, it can be classified and identified in two ways. One is divided into assembly-type RGV and transportation-type RGV according to function, mainly used for material transportation, workshop assembly, etc. ; Second, according to the motion mode, it can be divided into circular orbit type and linear reciprocating type. The circular orbit type RGV system has high efficiency and can work with multiple vehicles at the same time. The linear reciprocating type generally has only one RGV, which performs linear reciprocating motion, and the efficiency is relative to the circular RGV. The system is relatively low.

In terms of structure, RGV is mainly composed of frame, driving wheel, follower wheel, front and rear bumpers, chain conveyor, communication system, electrical system and various cover plates. Due to the simple structure of the RGV, it has strong anti-interference ability against the external environment, broad requirements for operators, strong operation stability, relatively few failures, relatively low overall maintenance costs, and high reliability.

It is also because RGV can only walk on the track. Once the RGV route is determined, it is more difficult and costly to rebuild. Therefore, the adaptability to the place of use and its own scalability are relatively poor.

3. The characteristics and applicable scenarios of

AGV. AGV cars can generally control their travel routes and behaviors through computers, or use electromagnetic tracks to set up their travel paths. The electromagnetic tracks are glued to the floor, and the unmanned vehicles rely on electromagnetic tracks. The incoming message moves and moves.

① Warehousing industry

Warehousing industry is the earliest application place of AGV. In 1954, the world's first AGV was put into operation in the warehouse of Mercury Motor Freight Company in South Carolina, USA, to realize the automatic transportation of goods in and out of the warehouse.

At present, there are about 20,000 AGVs of various kinds operating in 2,100 large and small warehouses in the world. In the three-dimensional warehouse of Haier Group's development zone that was put into operation in 2000, 9 AGVs formed a flexible automatic handling system in the warehouse, successfully completing 23,400 daily inbound and outbound goods and parts handling tasks.

② manufacturing

AGV in manufacturing production lines to show their talents, efficient, accurate, complete and flexible materials handling tasks. And a flexible logistics handling system can be composed of multiple AGVs, and the handling route can be adjusted in time with the adjustment of the production process, so that a production line can produce more than a dozen products, which greatly improves the flexibility of production and the competitiveness of the enterprise.

In 1974, in order to improve the flexibility of the transportation system, the Volvo Kalmar car assembly plant in Sweden adopted an automatic car assembly line based on AGVS as a carrier. The assembly line is composed of multiple AGVSs that can load car bodies. After adopting this assembly line, assembly time is reduced. By 20%, assembly failures were reduced by 39%, investment recovery time was reduced by 57%, and labor was reduced by 5%. At present, AGVs are widely used in the manufacturing and assembly lines of major automobile factories in the world, such as GM, Toyota, Chrysler, and Volkswagen.

In recent years, as the basic handling tool of CIMS, the application of AGV has penetrated into many industries such as machining, home appliance production, microelectronics manufacturing, cigarettes, etc. The production and processing field has become the most widely used field of AGV.

③ Post offices, libraries, ports, docks and airports.

In post offices, libraries, docks and airports, the transportation of goods has the characteristics of large changes in workload, strong dynamics, frequent adjustments of operating procedures, and single handling process. AGV The characteristics of parallel operation, automation, intelligence and flexibility can well meet the handling requirements of the above-mentioned occasions.

Sweden started to use AGV at the Stockholm Post Office in Greater Stockholm in 1983, Japan at the Tama Post Office in Tokyo in 1988, and China in 1990 at the Shanghai Post Hub to complete the handling of postal products. At the port of Rotterdam, the Netherlands, 50 AGVs called "yard tractors" complete the repetitive work of transporting containers from the side of the ship to a warehouse hundreds of yards away.

④ In tobacco, medicine, food, and chemical industries

that have special requirements for handling operations such as clean, safe, and pollution-free, the application of AGV is also valued. Many domestic cigarette companies, such as Qingdao Yizhong Group, Yuxi Hongta Group, Honghe Cigarette Factory, Huaiyin Cigarette Factory, use laser-guided AGV to complete the handling of pallet cargo.

4. The characteristics and application scenarios of IGV

As the result of continuous innovation and development of AGV technology, IGV has been further improved in terms of accuracy, safety, flexibility, and environmental adaptability.

In terms of flexible guidance, traditional AGV still needs to use QR codes, reflectors and other markers, while IGV adopts a new navigation method, relying on real-time scene maps, no other fixed markers, simple and flexible path changes...

IGV is suitable for flexible requirements In higher occasions, on the basis of satisfying the conventional handling functions, different functional modules can be selectively equipped according to the customer's technological process to meet the purpose of one vehicle for multiple uses, but the price is relatively high.

5. Future trend-integrated development.

In different scenarios, RGV, AGV, and IGV each play their own advantages, but with the development of technology, the future trend may be the integration of multiple functions, one vehicle with multiple uses, and maximum improvement Efficiency saves costs.

![[Depth] The rise of Chinese warehousing robot companies](http://www.agvblog.com/wp-content/themes/begin/thumbnail.php?src=http://www.agvblog.com/wp-content/uploads/2020/09/20200904102907-f2f5e.jpeg&w=280&h=210&a=&zc=1)